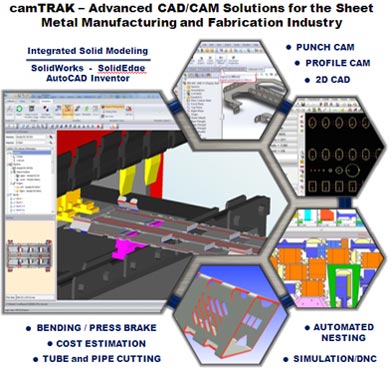

camTRAK is an integrated system covering the complete cycle required for the Sheet Metal Manufacturing Industry.

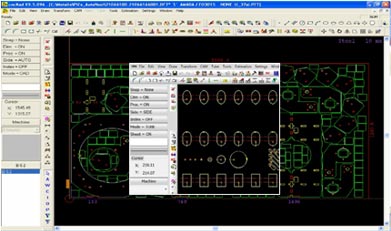

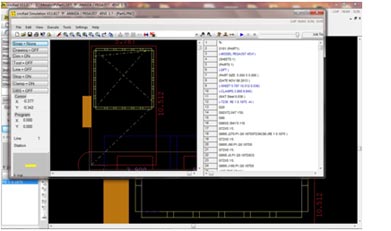

Drafting

camTRAK has a very powerful easy to use 2D drafting module . In addition to a full set of drafting tools, camTRAK supports special sheet metal drafting aids and Geometry Validation to automatically detect and correct unclosed contours.

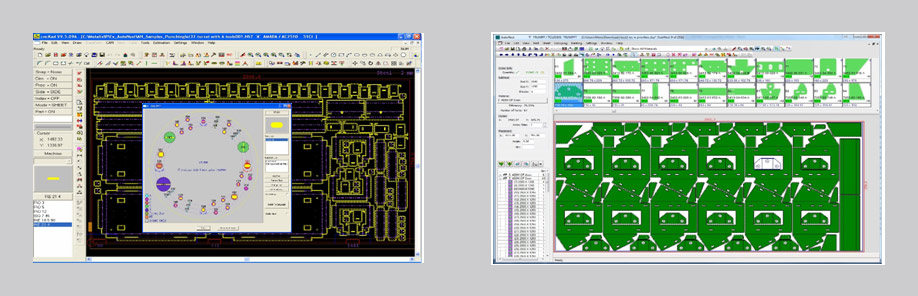

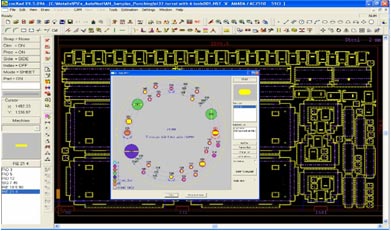

Punch Technology

The Punching module supports:

- Auto-Punch

- Special Tools

- Auto-Indexing

- Automatic reposition

- Common Cuts

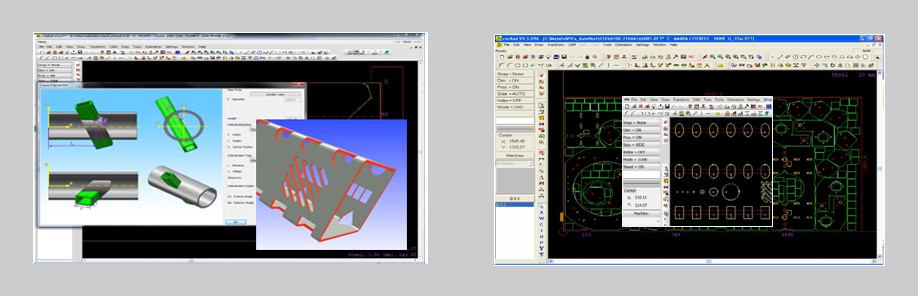

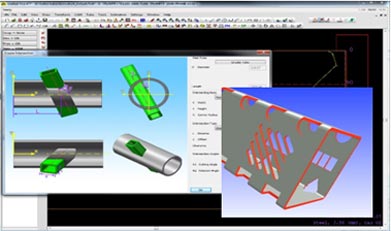

Tube Cutting

camTRAK supports Laser/Plasma/Flame machines equipped with a CNC Rotary Axis for tube processing, using a single graphic interface.

Set layout and design for cutting tube assemblies quickly and accurately , then view the cuts in 3D.

Set layout and design for cutting tube assemblies quickly and accurately , then view the cuts in 3D.

Simulation of CNC Programs

camTRAK supports graphic simulation of any CNC program, including legacy programs previously written on the machine.

The simulation enables easy editing of CNC programs, while graphically viewing the results on the processed sheet.

NC to Draft: Legacy NC files can be converted into drawings.

The simulation enables easy editing of CNC programs, while graphically viewing the results on the processed sheet.

NC to Draft: Legacy NC files can be converted into drawings.

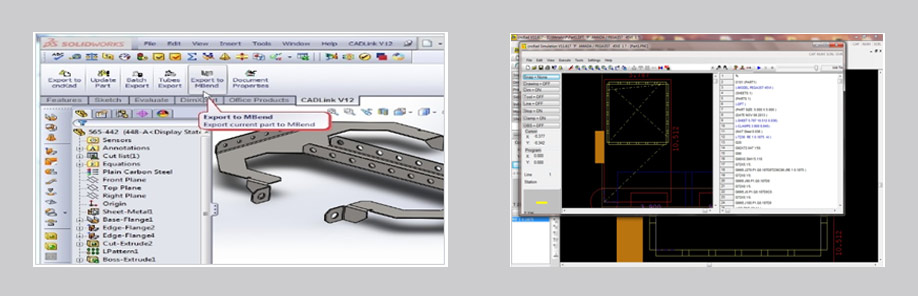

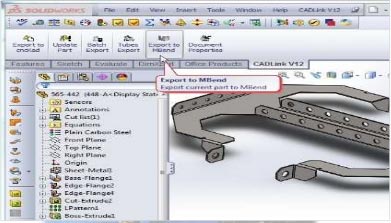

Import

camTRAK has an efficient import feature for DXF, DWG, IGES, CADL and other standard file formats.

Includes supports for mm/inch-based files and Layering.

Cutting Technology

- Auto-Cut

- Contour Check and Correction

- Beam Width definition and Auto Compensation

- Corner Loops and Corner Slow Down

- Z axis control

- Open Contour Cutting

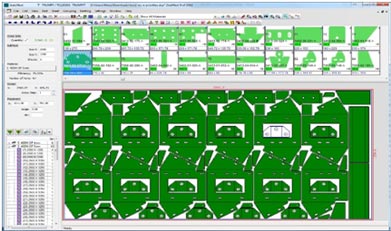

Post Processing: NC Files

Advanced post-processors generate efficient programs, including Sub-routines (macros), Optimized Tool Path and Minimal Turret Rotation, with support for machine operations such as oiling, vacuum and

DNC

Easy communication with your machine allowing for uploading and downloading of NC files, with support for batch loading and for extracting NC files from the machine controller.

Data Report Generation

Detailed production reports for individual parts, Nesting Solutions and Costing Estimation, using fully customizable templates.